What to Learn About Custom Enclosures in Metal Fabrication

- Importance and benefits of custom enclosures

- They provide housing and protection for equipment.

- Customization options cater to specific industry needs.

- Precision fabrication techniques and materials

- Techniques include laser cutting, welding, and powder coating.

- Materials used can be aluminum, stainless steel, or galvanized steel.

- How to choose a fabrication partner

- Consider experience, capabilities, lead times, and customer service.

Custom enclosures are essential components in many industries where sensitive equipment requires safe and secure housing. These enclosures are designed specifically to meet the unique requirements of each application, offering superior protection against environmental factors, physical damage, and interference. Unlike standard enclosures, custom solutions allow businesses to tailor every detail, ensuring optimal performance and long-term reliability. Investing in custom enclosures not only enhances equipment functionality but also helps reduce maintenance costs and increase operational efficiency over time.

Types of Custom Enclosures

Materials Used in Custom Enclosures

Custom enclosures are typically made from a variety of high-quality materials, each selected based on the specific needs of the application. Aluminum is often used for its lightweight and corrosion-resistant properties, making it ideal for outdoor or industrial settings. Stainless steel is preferred in environments where durability and resistance to rust are crucial. Galvanized steel is another popular choice, especially in harsh conditions where strength and longevity are key considerations.

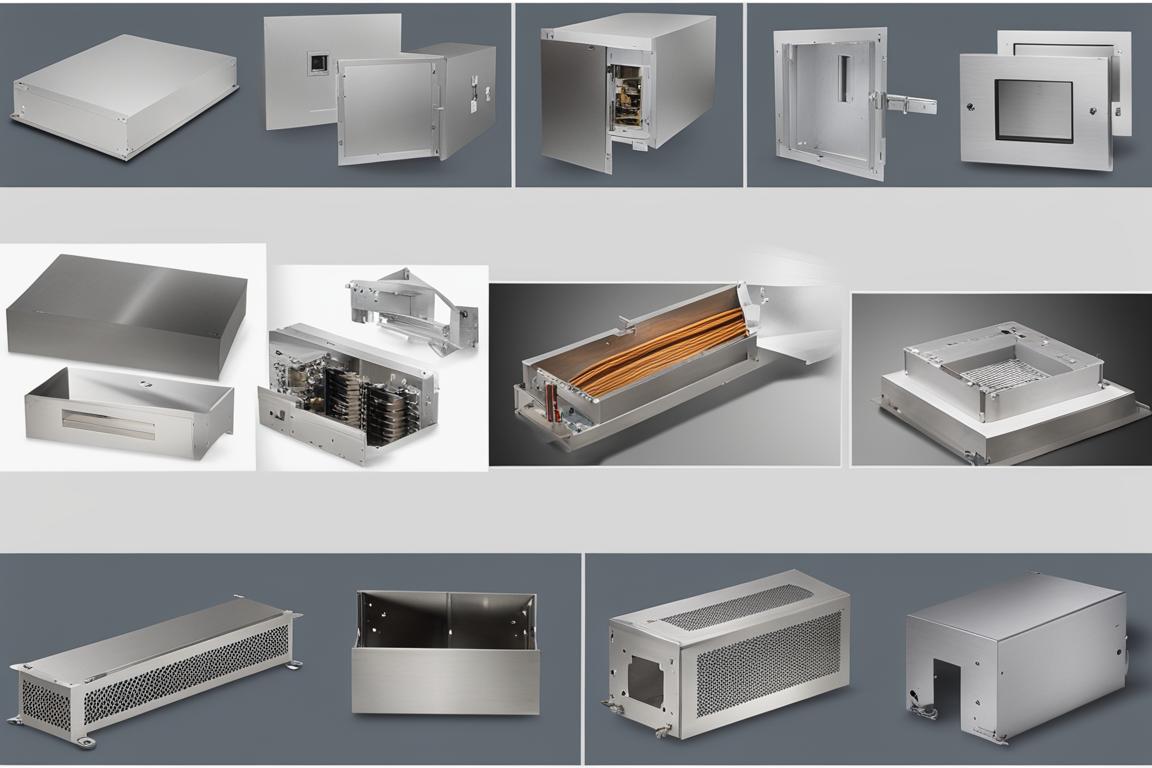

Varieties of Custom Enclosures

Custom enclosures come in a wide range of designs, including rackmount enclosures for data centers, console enclosures for control systems, and fully customized units that match unique specifications. The design flexibility allows for seamless integration with existing infrastructure while ensuring that equipment remains protected and easily accessible. This adaptability makes custom enclosures a versatile solution across multiple sectors.

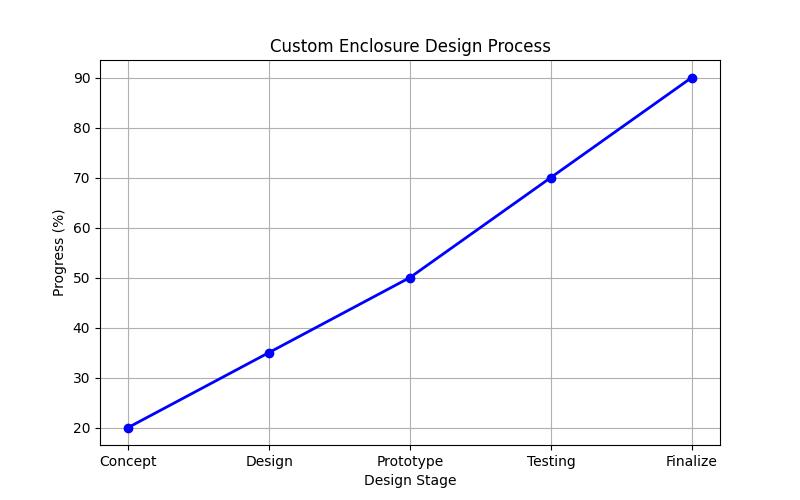

Design and Engineering of Custom Enclosures

The design process for custom enclosures involves careful planning and advanced engineering techniques. Computer-Aided Design (CAD) software is used to create precise 3D models, allowing engineers to test and refine the enclosure before production begins. This ensures that the final product meets all functional and aesthetic requirements. Engineers also take into account industry standards, safety regulations, and environmental conditions to ensure the enclosure performs optimally in its intended setting.

Precision Fabrication Techniques for Custom Enclosures

Fabrication Processes

Creating custom enclosures involves a series of precision-driven steps, including laser cutting, CNC punching, bending, welding, and powder coating. Each step is carefully executed to ensure accuracy and structural integrity. Laser cutting allows for intricate shapes and clean edges, while welding ensures strong and durable joints. Powder coating provides a protective and aesthetically pleasing finish that resists wear and tear over time.

Importance of Precision

Precision is critical when manufacturing custom enclosures, as even small errors can affect performance and safety. Maintaining high levels of accuracy throughout the fabrication process ensures that the final product fits perfectly and functions as intended. This attention to detail helps prevent costly rework and guarantees that the enclosure meets all quality and safety standards.

Customization Options for Enclosures

Tailored Features

Custom enclosures offer a wide array of customization options, such as different sizes, ventilation systems, mounting solutions, door configurations, and surface finishes. These features can be tailored to suit the specific needs of the equipment being housed. For example, ventilation systems help manage heat dissipation, while specialized door designs improve access and security. This level of personalization ensures that the enclosure is both functional and efficient for its intended use.

Industry-Specific Customization

Manufacturers often customize enclosures to meet the unique demands of various industries. For instance, IP ratings are used to determine the level of protection against dust and water, which is essential in outdoor or industrial environments. EMI/RFI shielding is important in electronics to prevent electromagnetic interference, and NEMA standards ensure that enclosures are suitable for hazardous locations. These customizations make enclosures more effective and reliable in their specific applications.

Quality Control and Testing Procedures

Ensuring Quality

Quality control is a vital part of the custom enclosure manufacturing process. Manufacturers implement rigorous testing procedures to verify that each enclosure meets the required standards. This includes checking for structural integrity, dimensional accuracy, and material quality. Inspections are conducted at various stages of production to identify and correct any issues before the final product is delivered.

Certifications and Standards

Many manufacturers hold certifications such as ISO 9001:2015, which confirms their commitment to quality management systems. Compliance with industry standards like ASME, ASTM, and MIL-STD ensures that enclosures are built to last and perform reliably. These certifications give clients confidence in the quality and consistency of the products they receive.

| Quality Control and Testing Procedures | Applications of Custom Enclosures |

|---|---|

| – Quality control measures ensure fabrication standards are met | – Telecommunications: safeguarding sensitive equipment |

| – Compliance with industry standards like ISO 9001:2015 | – Electronics: organizing and protecting components |

| – Rigorous testing procedures to guarantee reliability | – Healthcare: optimizing equipment performance |

| – Inspections at various stages of production | – Aerospace: enhancing safety measures |

Applications of Custom Enclosures

Custom enclosures are used in a wide range of industries where equipment protection, organization, and accessibility are essential. In telecommunications, they protect sensitive hardware from environmental damage. In the electronics sector, they help manage and safeguard components. In healthcare, they ensure medical devices function reliably. And in aerospace, they contribute to the safety and performance of critical systems. Their versatility makes them an essential part of modern industrial infrastructure.

Case Studies on Custom Enclosures

Real-World Success Stories

Many companies have successfully implemented custom enclosures to solve complex challenges and improve operational efficiency. For example, one manufacturer improved equipment reliability by using custom enclosures with enhanced ventilation and EMI shielding. Another company streamlined its workflow by integrating modular enclosures into its facility. These case studies demonstrate how custom solutions can enhance performance, reduce downtime, and improve overall productivity in various industries.

Future Trends in Custom Enclosures

Technological Advancements

The future of custom enclosures is shaped by continuous innovation in technology and manufacturing. Emerging trends include the integration of smart sensors for real-time monitoring, the use of sustainable materials for eco-friendly designs, and the adoption of automation to improve production speed and accuracy. These advancements are helping manufacturers deliver more efficient, customizable, and environmentally responsible solutions to meet the evolving needs of industries worldwide.

Selecting a Fabrication Partner for Custom Enclosures

Choosing the Right Partner

When selecting a fabrication partner for custom enclosures, it's important to evaluate their experience, capabilities, and reputation. A reliable partner should have expertise in precision sheet metal fabrication, the ability to handle complex designs, and a track record of delivering projects on time. Good communication and customer support are also key factors to consider. Working with a trusted fabricator ensures that your custom enclosures meet your exact specifications and quality expectations.

Conclusion

In summary, custom enclosures are a vital component in many industries, providing tailored solutions for equipment protection and performance. From material selection and design to fabrication and quality control, every aspect plays a role in ensuring that the final product meets the highest standards. By investing in custom enclosures, businesses can enhance equipment reliability, reduce maintenance costs, and achieve greater operational efficiency. Whether you're looking for a simple housing solution or a highly specialized unit, custom enclosures offer the flexibility and quality needed to support your industrial needs.

For innovative enclosure solutions, explore Protocase’s custom electronic enclosures. If you’re looking for expandable and stackable options, check out Custom Cages’ large reptile enclosures.

For expert assistance in designing and manufacturing custom enclosures tailored to your specific needs, contact us today!

Questions and Answers

Who can benefit from custom enclosures in precision sheet metal fabrication?

Companies in industries like electronics, telecommunications, and medical devices.

What materials are typically used for custom enclosures in sheet metal fabrication?

Common materials include aluminum, stainless steel, and galvanized steel.

How are custom enclosures designed and manufactured in precision sheet metal fabrication?

They are designed using CAD software and then fabricated using cutting, bending, and welding techniques.

What makes custom enclosures from precision sheet metal fabrication more costly?

The customization and precision involved in the design and manufacturing process can lead to higher production costs.

How can I ensure that my custom enclosure meets industry standards and regulations?

Work with a reputable sheet metal fabrication company that has experience in your industry and adheres to quality standards.

{"@context":"https://schema.org","@type":"FAQPage","mainEntity":[{"@type": "Question", "name": "Who can benefit from custom enclosures in precision sheet metal fabrication?", "acceptedAnswer": {"@type": "Answer", "text": "Companies in industries like electronics, telecommunications, and medical devices."}}, {"@type": "Question", "name": "What materials are typically used for custom enclosures in sheet metal fabrication?", "acceptedAnswer": {"@type": "Answer", "text": "Common materials include aluminum, stainless steel, and galvanized steel."}}, {"@type": "Question", "name": "How are custom enclosures designed and manufactured in precision sheet metal fabrication?", "acceptedAnswer": {"@type": "Answer", "text": "They are designed using CAD software and then fabricated using cutting, bending, and welding techniques."}}, {"@type": "Question", "name": "What makes custom enclosures from precision sheet metal fabrication more costly?", "acceptedAnswer": {"@type": "Answer", "text": "The customization and precision involved in the design and manufacturing process can lead to higher production costs."}}, {"@type": "Question", "name": "How can I ensure that my custom enclosure meets industry standards and regulations?", "acceptedAnswer": {"@type": "Answer", "text": "Work with a reputable sheet metal fabrication company that has experience in your industry and adheres to quality standards."}}]}Hardware Automatic Processing Equipment

Hardware Automatic Processing Equipment,Automatic Packaging Production Line,Automatic Tapping Machine Equipment,Metal Slot Sawing Machine

Shenzhen Yonglun Intelligent Equipment Technology Co., LTD , https://www.foyooo.com

![<?echo $_SERVER['SERVER_NAME'];?>](/template/twentyseventeen/skin/images/header.jpg)