What to Learn About Custom Enclosures in Metal Fabrication

- Understanding the importance and benefits of custom enclosures

- They provide secure housing and protection for sensitive equipment

- Customization allows for tailored solutions that meet specific industry needs

- Advanced fabrication techniques like laser cutting, welding, and powder coating are used

- Materials such as aluminum, stainless steel, and galvanized steel are commonly selected

- Choosing the right fabrication partner is crucial for quality and reliability

- Factors to consider include experience, capabilities, lead times, and customer support

Custom enclosures play a vital role in industries where equipment must be safeguarded from environmental factors, physical damage, or operational risks. These enclosures are not just functional but also designed to enhance performance and durability. Whether it's for electronics, medical devices, or industrial machinery, custom enclosures offer a unique solution that standard models cannot match. By choosing custom enclosures, businesses can ensure their equipment remains protected, efficient, and easy to maintain.

Types of Custom Enclosures

Common Materials Used

Custom enclosures are typically made from materials like aluminum, which is lightweight and corrosion-resistant; stainless steel, known for its strength and durability; and galvanized steel, ideal for harsh environments. Each material has its own advantages, making it possible to choose the best option based on the application’s requirements and environmental conditions.

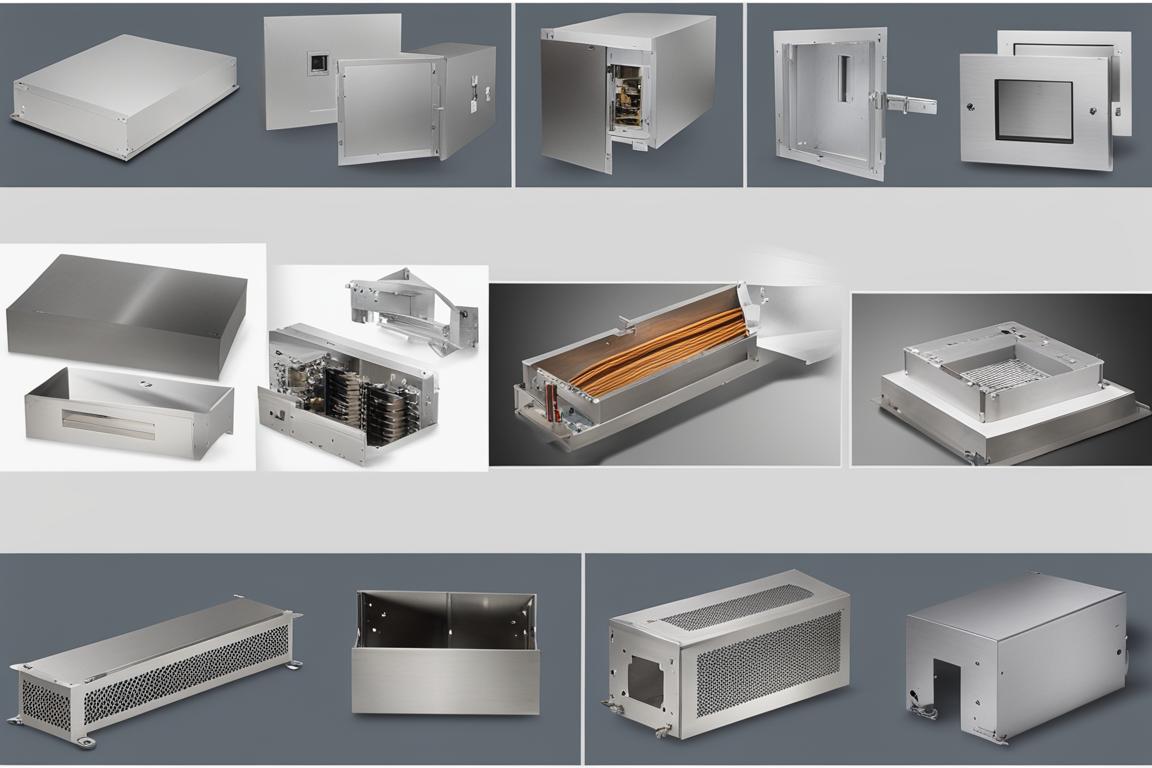

Diverse Design Options

From rackmount enclosures that allow for efficient stacking of equipment to console enclosures that provide centralized control, there are countless design options available. Fully customized enclosures can be built to fit any space or function, ensuring optimal protection and accessibility for the components they house.

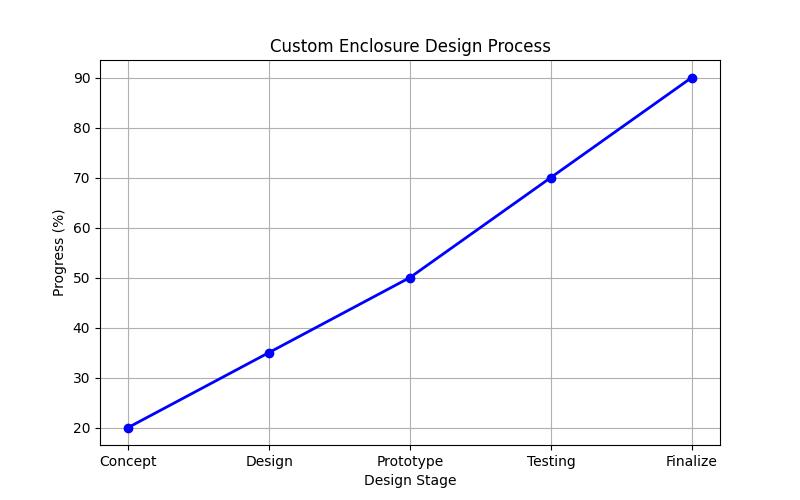

Design and Engineering of Custom Enclosures

The design process for custom enclosures involves careful planning and advanced tools like CAD software. This ensures that every detail is precise, allowing for accurate prototyping and testing before final production. Engineers follow strict standards to guarantee that the enclosures meet all functional and safety requirements, providing long-term value and reliability.

Precision Fabrication Techniques

Key Fabrication Methods

Fabrication processes such as laser cutting, CNC punching, bending, and welding are used to shape and assemble enclosure components with high accuracy. Powder coating is often applied for both aesthetic appeal and added protection against wear and tear. These methods ensure that each part fits perfectly, enhancing the overall quality and performance of the final product.

Why Precision Matters

Precision in fabrication is essential to ensure that the enclosure functions as intended. Even small deviations can affect the fit, performance, and longevity of the enclosure. Maintaining high standards of precision helps manufacturers deliver reliable products that meet or exceed client expectations.

Customization Features

Tailored Design Elements

Custom enclosures can be modified to suit specific needs, including different sizes, ventilation systems, mounting options, door types, and surface finishes. These features help ensure that the enclosure is not only functional but also user-friendly and aesthetically pleasing.

Industry-Specific Adaptations

Enclosures can be adapted to meet the unique demands of various industries. For example, IP ratings ensure protection against dust and water, while EMI/RFI shielding reduces interference. NEMA standards define how enclosures perform in hazardous locations, making them suitable for critical applications.

Quality Assurance and Testing

Importance of Quality Control

Rigorous quality checks and testing procedures are essential to ensure that custom enclosures meet all required standards. From material selection to final assembly, every step is monitored to maintain consistency and reliability. This attention to detail guarantees that the final product performs optimally in real-world conditions.

Certifications and Compliance

Many manufacturers hold certifications like ISO 9001:2015, which confirms their commitment to quality management. Compliance with industry standards ensures that enclosures are safe, durable, and capable of performing under demanding conditions. This builds trust between the manufacturer and the client.

| Quality Control and Testing Procedures | Applications of Custom Enclosures |

|---|---|

| – Quality control measures ensure fabrication standards are met | – Telecommunications: protecting sensitive equipment |

| – Compliance with industry standards like ISO 9001:2015 | – Electronics: organizing and protecting components |

| – Rigorous testing procedures to guarantee reliability | – Healthcare: optimizing equipment performance |

| – Inspections at various stages of production | – Aerospace: enhancing safety and efficiency |

Real-World Applications

Custom enclosures are used across multiple industries, including telecommunications, healthcare, aerospace, and more. They protect sensitive equipment, improve organization, and enhance safety. Manufacturers tailor designs to meet the specific challenges of each industry, offering customized solutions that boost performance and reduce downtime.

Case Studies and Success Stories

Real-World Examples

Many companies have successfully implemented custom enclosures to solve complex problems and improve their operations. These case studies show how custom solutions can streamline workflows, increase efficiency, and improve safety. The results speak for themselves, proving the value of investing in high-quality, tailored enclosures.

Future Trends in Custom Enclosures

Innovative Developments

The future of custom enclosures is shaped by technological advancements such as smart monitoring systems, eco-friendly materials, and automation. These innovations are helping manufacturers create more efficient, sustainable, and high-performing enclosures that meet the evolving needs of modern industries.

Selecting the Right Fabrication Partner

Key Considerations

Choosing the right fabrication partner is essential for getting the best results. Look for a company with proven experience, advanced capabilities, and a track record of delivering high-quality enclosures on time. A strong partnership ensures that your custom enclosure meets your exact specifications and supports your business goals.

Conclusion

In summary, custom enclosures are an essential part of many industries, offering tailored protection and functionality for equipment. With precision manufacturing, customization, and strict quality control, these enclosures provide long-lasting value. Investing in custom enclosures not only improves operational efficiency but also demonstrates a commitment to excellence and innovation in metal fabrication.

For innovative enclosure solutions, explore Protocase’s custom electronic enclosures. If you need expandable and stackable options, check out Custom Cages’ large reptile enclosures.

For expert assistance in designing and manufacturing custom enclosures, contact us today!

Frequently Asked Questions

Who can benefit from custom enclosures in metal fabrication?

Companies in industries like electronics, telecommunications, and medical devices can benefit from custom enclosures, as they require specialized protection for sensitive equipment.

What materials are commonly used in custom enclosures?

Aluminum, stainless steel, and galvanized steel are frequently used due to their durability, corrosion resistance, and versatility.

How are custom enclosures manufactured?

Custom enclosures are designed using CAD software and then fabricated using techniques like laser cutting, bending, and welding.

Why are custom enclosures more expensive?

The level of customization, precision, and complexity involved in the design and manufacturing process can result in higher costs.

How do I ensure my custom enclosure meets industry standards?

Partner with a reputable fabrication company that has experience in your field and follows quality assurance protocols and industry regulations.

{"@context":"https://schema.org","@type":"FAQPage","mainEntity":[{"@type": "Question", "name": "Who can benefit from custom enclosures in metal fabrication?", "acceptedAnswer": {"@type": "Answer", "text": "Companies in industries like electronics, telecommunications, and medical devices."}}, {"@type": "Question", "name": "What materials are commonly used in custom enclosures?", "acceptedAnswer": {"@type": "Answer", "text": "Aluminum, stainless steel, and galvanized steel are frequently used."}}, {"@type": "Question", "name": "How are custom enclosures manufactured?", "acceptedAnswer": {"@type": "Answer", "text": "They are designed with CAD software and then fabricated using techniques like laser cutting and welding."}}, {"@type": "Question", "name": "Why are custom enclosures more expensive?", "acceptedAnswer": {"@type": "Answer", "text": "The customization and precision involved in the process can lead to higher costs."}}, {"@type": "Question", "name": "How do I ensure my custom enclosure meets industry standards?", "acceptedAnswer": {"@type": "Answer", "text": "Work with a reputable fabrication company that follows quality protocols and industry regulations."}}]}Disposable Cigarette Assembly Equipment

Disposable Cigarette Assembly Equipment,Fully Automatic Electrode Assembly Equipment,Accessories Assembly Equipment,Electronic Cigarette Parts Assembly Equipment

Shenzhen Yonglun Intelligent Equipment Technology Co., LTD , https://www.foyooo.com

![<?echo $_SERVER['SERVER_NAME'];?>](/template/twentyseventeen/skin/images/header.jpg)