Quick Connect Fittings: Enhancing Efficiency in Hydraulic Systems

In the fast-paced world of hydraulic systems, efficiency and reliability are key to maintaining performance. Among the many components that contribute to this, quick connect fittings have become a game-changer. These fittings are designed for rapid and secure connections, making them ideal for applications where time is critical. Whether it's for maintenance, system reconfiguration, or emergency repairs, quick connect fittings streamline the process, reducing downtime and improving overall productivity.

The Simple Mechanics Explained

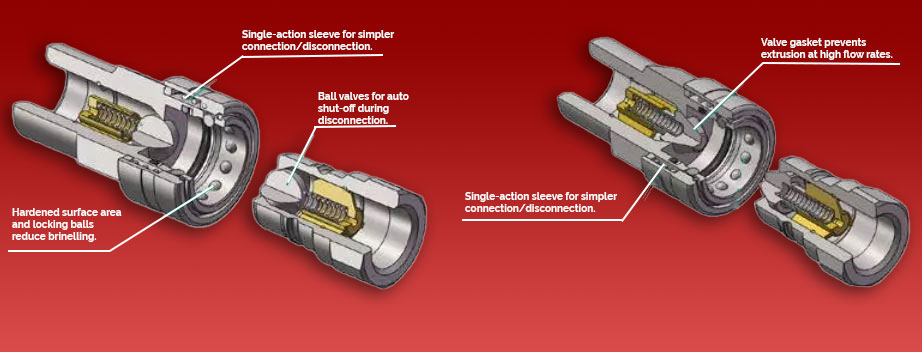

The operation of quick connect fittings is both simple and effective. They typically consist of two parts: a male plug and a female coupler. When the male end is inserted into the female coupler, an internal locking mechanism engages automatically, securing the connection. This mechanism often involves ball bearings or similar devices that lock around the male plug, ensuring a tight seal. The design allows for a leak-free connection, which is crucial for maintaining the integrity of the hydraulic system. To disconnect, a release button or sleeve on the female coupler is pressed or pulled, disengaging the locking mechanism and allowing the male plug to be removed easily. This tool-free process makes maintenance faster and more efficient, especially in industrial environments where time is money.

Materials Matter: Choosing the Right Quick Connect Fittings for Your Hydraulic System

Selecting the right material for quick connect fittings is essential for optimal performance. Common materials include brass, known for its corrosion resistance and conductivity; plastic, which is lightweight and cost-effective for less demanding applications; and stainless steel, prized for its strength, durability, and resistance to corrosion. Stainless steel fittings are particularly suitable for harsh environments where exposure to extreme temperatures or corrosive fluids is common. Their ability to withstand high pressure and resist wear ensures long-term reliability, making them a top choice for heavy-duty hydraulic systems. Additionally, the design of these fittings can vary, from straight connectors to elbows and tees, offering flexibility in installation and space optimization.

Conclusion

Quick connect fittings play a vital role in modern hydraulic systems by offering a reliable, efficient, and safe way to manage fluid flow. Their ability to enable rapid, tool-free connections and disconnections significantly reduces downtime, enhances productivity, and improves overall system performance. Whether in manufacturing, construction, or agriculture, these fittings provide a flexible solution that adapts to different operational needs. As hydraulic technology continues to evolve, quick connect fittings remain at the forefront, ensuring smooth and efficient fluid control across a wide range of industries.

Frequently Asked Questions:

How do hydraulic quick couplers work?

Answer: Hydraulic quick couplers are designed to allow fast and secure connections between hydraulic hoses and equipment. They consist of two parts: a male plug and a female coupler. Each has a built-in valve that remains closed until the two parts are connected. When the male plug is inserted into the female coupler, the valves open, allowing fluid to flow. A locking mechanism inside the coupler secures the connection, while seals prevent leaks. To disconnect, a release mechanism is activated, closing the valves and allowing the male plug to be removed safely. This system enables quick, tool-free connections, making it ideal for frequent use in industrial settings.

How to disconnect quick connect fittings?

Answer: Disconnecting quick connect fittings is a straightforward process, but it should always be done with caution. First, ensure the hydraulic system is depressurized to avoid accidents. Locate the release mechanism on the female coupler, which may be a button, ring, or sleeve. Depending on the design, you may need to push, pull, or twist it to unlock the connection. Once the mechanism is engaged, gently pull the male plug out of the female coupler. After disconnection, inspect both ends for any signs of damage or wear, and replace if necessary. Always follow the manufacturer’s guidelines to ensure safe and proper operation of the fittings.

Arc Toothed Pu Timing Belt,Conveyor Mesh Belt,Stainless Steel Wire Mesh Conveyor Belt,Transmission Belts

Jiangsu Bailite Transmission Technology Co., Ltd , https://www.zsindustrialbelt.com

![<?echo $_SERVER['SERVER_NAME'];?>](/template/twentyseventeen/skin/images/header.jpg)