Product Description

Cow Milk Vacuum Pump for Portable Milking MachineSpecification:

Â

| Capacity (L/min) | 220 | 280 | 550 | 850 | 1500 | 2100 |

| Pump Speed (r/min) | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 |

| Vacuum Degree (Kpa) | 50 | 50 | 50 | 50 | 50 | 50 |

| Noise (dB(A)) | ≤50 | ≤50 | ≤60 | ≤70 | ≤70 | ≤70 |

| Ultimate Vacuum (MP) | ≤90 | ≤90 | ≤90 | ≤90 | ≤90 | ≤90 |

| Motor Power (KW) | 1.1 | 1.1 | 2.2 | 3 | 4 | 5.5 |

| Weight (KG) | 13.5 | 14 | 31 | 36 | 57.5 | 69.5 |

| Size (L*W*H) (mm) | 230*220*220 | 230*220*220 | 280*270*220 | 300*220*220 | 430*230*230 | 390*290*290 |

Note: The above parameters are for reference only!

Â

Features:

- Suitable for milking parlor, automatic milking system, and milking machine;

- Comfortable and reasonable appearance design

- Reasonable silencer to reduce the noise

- Fast and efficient vacuum air circulation

- Perfect oil pot, saves oil usage

- Has a perfect gas cycle

- Comfortable appearance design

- Installs fuel valve to help control oil wastage

- Reasonable silencer design reduces noise

Â

Application:

The vacuum pump is the heart of the milking machine. Its function is to extract air from the milking machine system through belt-driven operation.

Â

Description:

The vacuum pump is the core component of the milking machine. Regular maintenance helps preserve the vacuum reserve. Various capacity vacuum pumps with different motor power are available for selection. The heavy-duty body of the rotary vane vacuum pump is made from chemical-resistant cast iron, making it durable in any environmental working conditions.

Â

The function of the vacuum pump is to extract air from the milking machine system through belt-driven operation. This milking machine vacuum pump offers flexibility with speeds ranging from about 800-1500 r/min and corresponding pump capacities to suit different sizes of milking machines.

Â

A complete set of milk vacuum pump consists of a vacuum pump, silencer (stainless steel muffler), oil can (oil pot), belt (pulley), and some rubber parts. The pump vanes of the vacuum pump kits are made of fiber material.

Packaging Details

- Outer package: standard export wooden case

- Inner package: plastic bag

- Negotiable according to buyer's special requirements

Sample photos :

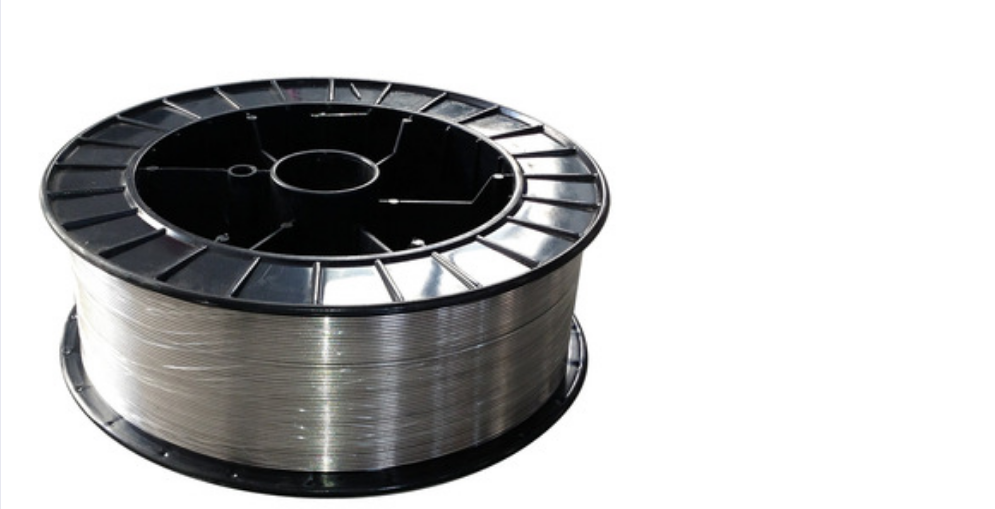

Metals, alloys and composite powders commonly used in thermal spray hardfacing technology and coating service. These unique powders are instantly heated by thermal spraying (welding) methods such as high temperature flame or explosive flame, and are sprayed and deposited on the cold or hot workpiece surface with high-speed heat flow in a molten or semi-melted state to form a surface Reinforcing layer, in order to improve the wear resistance, corrosion resistance, heat resistance, oxidation resistance or repair of external dimensions of the workpiece surface. XTC produces WC, CrC, Oxide Ceramic, Boride Powder, Metal Alloy Powder, Pure Metal and Spray Wire, etc. product. For HVOF/HVAF/plasma/Flame spray coating and applications. Meet the wear and corrosion resistance requirements of different surfaces.

WC, CrC oxide ceramic powder and boride products are excellent in wear resistance and high temperature corrosion resistance. Taking WC products as an example, the hardness can reach HV1300-1500, and the temperature of CrC products can reach 800 degrees Celsius.

Metal alloy powder, Pure Metal and Spray Wire products have more applications in glass mold, steel and machinery industries. And XTC products are now become more and more popular in Metal spray coating and thermal spray coating industry.

Coating Service,Metal Spray Coating,Flame Spray Coating,Thermal Spray Coating

Luoyang Golden Egret Geotools Co., Ltd. , https://www.xtc-thermalspray.com

![<?echo $_SERVER['SERVER_NAME'];?>](/template/twentyseventeen/skin/images/header.jpg)