- Model No.: VA-440

- Usage: Incubation Equipment

- Power Source: Electric

- Epidemic Prevention Equipment: Medicated Bath Equipment

- Condition: New

- Appearance: Color Structure of Aluminum Alloy

- Control Mode: Full Automatic

- Warranty: 3 Years

- Egg Incubator Hatching Rate: ≥98%

- Trademark: Vena Egg Incubator

- Origin: Jiangxi

- Type: Chicks Hatching Machine

- Application: Chicken

- Heating and Ventilation Equipment Type: Steam or Hot Water Heating

- Certification: CE

- Brand Name: Vena Egg Incubator

- Working Lifetime: 14–16 Years

- After-Sales Service Provided: Overseas Service Center Available

- Packaging Detail: Wooden Package

- Delivery Detail: Within 3–7 Days Once Payment Confirmed

- Specification: CE

- HS Code: 8436210000

We offer a wide range of digital egg incubators, from 48 to 22528 eggs, all fully automatic and CE certified. When you purchase our egg incubator, we provide a free set of spare parts including the temperature heater, egg turning motor, humidity heater, and egg tester. In addition, we also supply mini incubators such as VA-48, VA-96, and plucker machines like VN-40, VN-50, VN-60, and VN-80.

Brief Introduction of Egg Incubator:

1. Micro-computer controlled on temperature & humidity;

2. Energy can be electricity, coal, gas, etc.

3. Automatic egg turning, automatic alarm on temperature & humidity.

Main Material of Egg Incubator:

1. Exterior structure in colorful steel plate;

2. The edge covered by aluminum alloy.

Features of Egg Incubator:

1. Digital display with temperature and humidity controlled by micro-computer.

2. Energy could be supplied by electricity & coal.

3. Automatic egg turning, automatic alarm on temperature & humidity.

4. Automatic watering system.

5. New-design looking with two kinds of colors (white or blue, please tell us which you want).

6. Larger window for you to see all the hatching process inside.

7. It is suitable for different kinds of eggs like chicken eggs, duck eggs, quail eggs with different egg trays.

8. With the capability from 48 to 22528 eggs, the larger or smaller can be customized.

9. Easy to install, saving human resource and budget to maximize your profit.

10. CE certificate for the Quality.

11. Energy-saving and environment protection.

12. Egg incubator Hatching rate more than 98%.

13. Incubator and hatcher combined machine, no need you to buy hatcher extra.

Free Spare Parts of Digital Egg Incubator for You:

*1 Egg Tester

*1 Temperature Heating Element

*1 Humidity Heating Element

*1 Travel Switch

*1 Egg Candling Light

Full Technology and Function of Egg Incubator:

1. Automatic turning system tilting the eggs 45° once every two hours. According to your actual request, you can set the turning interval time you need.

2. Big middle fan with automatic heating and roller humidifying system.

3. Backup emergency and alarming system for safe use.

4. Automatic air cooling system and automatic ventilator.

5. Inside light.

6. Made of polyester, double wall construction for perfect insulation.

7. Trolley egg-frame for easy operation, inside disinfecting and cleaning.

| Brand | Vena Egg Incubator |

| Model name | VA-1056 |

| Quality certificate | CE |

| Condition | New |

| Warranty | 3 years |

| Working lifetime | 14–16 years |

| Price | Competitive price with a set of spare parts for free |

| Spare parts | Egg turning motor, temperature heating element, egg candling light |

| Packing details | Wooden packing to avoid shipping damages |

| Hatching rate | More than 98% |

| Color | White or blue |

| Material | Colorful steel plate and edge with aluminum alloy |

| Chicken | 1056 eggs |

| Duck | 756 eggs |

| Bird/Quail | 2652 eggs |

| Goose | 432 eggs |

| Appearance | Exterior structure in colorful steel plate |

| Use voltage | 100V–120V or 220V–240V AC 50/60 Hz |

| Temperature set range | 0–99.9°C |

| Temperature measurement accuracy | ±0.1°C |

| Temperature control accuracy | ≤ ±0.1°C |

| Humidity display range | 0–99%RH |

| Humidity precision control | ±5%RH |

| Output approach | (Medium) 4 (temperature control, left-over eggs, right over the egg, alarm) |

| (High) 7 Road | (over-temperature, temperature control, low temperature, humidity control, left-over eggs, right over the egg, alarm) |

| Output current | Temperature Control 220V 10A, the other 200V 1A |

| Over egg cycle | 0.1–99.9 hour (Factory settings 1.5 hour) |

| Eggs over time | 1–255 seconds adjustable (factory set to 180 seconds) |

| Doubled the number of eggs | Maximum record 999 times |

| Ventilation cycle | 5–999 minutes (adjustable, factory 0 hours, non-ventilation) |

| Ventilation time | 0–999 seconds (adjustable, factory 30 seconds) |

| Measurement of the line is long | 1.5M |

| Operating voltage | AC180V–240V, 50Hz |

| Relative humidity | Less than 85% |

| Ambient temperature | -10°C–40°C |

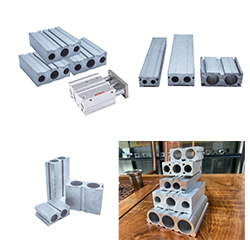

TCN/TN Pneumatic Cylinder Barrel

Guided pneumatic cylinder adds another guided rod on the basis of the single rod or double rod cylinders to make the movement trajectory of the cylinder more accurate, which can effectively increase the performance of resisting side load and reduce the influence of lateral swing. Most regular guided air cylinder is MGP series.Pneumatic Cylinder Tube.

Both dual rod air cylinder and guided air cylinder have a magnetic ring inside, which is convenient for the magnetic switch to detect the position of the piston movement. There are mounting holes on three sides of the fixed plate of double rod air cylinder and guided pneumatic cylinder, which are convenient for multi-directional installation and use.Air Cylinder Barrel.

Parameter:

â—† Working pressure: 0.15~0.7MPa

◆ Ambient temperature: -20~70℃

â—† Applicable fluid medium: Compressed air, non-corrosive gas

â—† Operating speed: 50-500mm/s

A three-axis cylinder typically refers to the use of three independent linear cylinders in a system to achieve motion in three-dimensional space. In automation and robotics technology, such configurations can be used to achieve precise position control and object movement. Each cylinder is typically responsible for one axial movement (e.g. X, Y, Z).

Here are some key points about three-axis cylinders:

Structure:

Usually composed of three independent linear cylinders.

Each cylinder is installed in a mutually perpendicular direction, forming a three-dimensional coordinate system.

Application:

Part positioning on automated assembly lines.

Position adjustment of end effectors in industrial robots.

Accurate movement in material handling systems.

Sample processing in laboratory equipment.

working principle:

By compressing air, the piston is pushed to move inside the cylinder.

The extension and contraction of the piston rod drives the mechanical structure to move along a specified axis.

The combined motion of three axes can achieve complex spatial trajectories.

Control system:

PLC (Programmable Logic Controller) or specialized motion controller may be required to coordinate the actions of the three cylinders.

Sensors are used to provide feedback on position information to ensure precise control.

characteristic:

Compact structure, suitable for application environments with limited space.

Quick action, suitable for high-speed operation scenarios.

Maintenance is relatively simple because the main components are pneumatic.

Dual axis cylinder usually refers to a specially designed pneumatic actuator that can generate motion in two directions. This type of cylinder is typically used in applications that require linear motion on two axes simultaneously or separately. Here is some basic information about dual axis cylinders:

Basic concepts

Definition: A dual axis cylinder is a pneumatic component capable of producing linear motion on two axes simultaneously or separately.

Application: Widely used in automated production lines, material handling, precision positioning, and other situations that require multi axis control.

Structure and Type

Parallel dual axis cylinder: Two cylinders are arranged in parallel, and the piston rod can move synchronously or independently.

Coaxial dual axis cylinder: Two cylinders share a piston rod and control the movement of the two shafts through different air paths.

Other types: There are also specially designed dual axis cylinders, such as dual piston rod cylinders, which can install two piston rods on one cylinder block.

working principle

Compressed air drive: By using compressed air to push the piston inside the cylinder, it drives the piston rod or connecting piece to move along a predetermined axis.

Independent or synchronous control: Depending on the needs, the motion of each axis can be independently controlled, or two axes can be synchronized through specific design.

Control system

Electromagnetic valve: used to control the direction of airflow, thereby controlling the expansion and contraction of the cylinder.

Sensors: Displacement sensors or proximity switches can be installed to monitor the position of the piston and achieve precise control.

PLC or controller: It is usually necessary to coordinate the working sequence and speed of the cylinders through PLC or other controllers.

Application examples

Automated assembly: Dual axis cylinders can be used for positioning, clamping, or assembling parts.

Robot arm: As a part of the end effector of the robot, it achieves grasping and placing tasks.

Testing equipment: used in laboratories or quality control environments to simulate pressure or thrust testing.

characteristic

Compact: Compared to using two cylinders separately, dual axis cylinders have an advantage in space occupation.

Flexibility: Different travel lengths and installation methods can be customized according to application requirements.

Economy: Reduce installation space and costs while maintaining high performance.

TCN Pneumatic Cylinder Barrel,TN Pneumatic Cylinder Barrel,Dual Rod Air Cylinder Aluminum Tube,Dual Rod Air Cylinder Tube

Foshan Weiyingjia Technology Co., Ltd , https://www.wyspneumatic.com

![<?echo $_SERVER['SERVER_NAME'];?>](/template/twentyseventeen/skin/images/header.jpg)