Sheet Metal Hole CNC Turret Punching Machine Application:

CNC turret punching machine is a mechatronics automation equipment widely used in the chassis cabinets processing, air conditioners, refrigerators, range hoods, instruments, electric control cabinet panels, battery plates, building decorative materials, auto parts, silencing plates, lamps, kitchen equipment, and other sheet metal processing industries.

Main Specifications of the Mechanical CNC Turret Punching Machine:

|

Specification |

Unit |

AMD-255 |

|

Transmission Mode |

/ |

Mechanical |

|

Punch Force |

kN |

250 (Standard)/300 |

|

Power Rating |

kW |

11 |

|

Processing Sheet Size |

mm |

2500 x 1250 |

|

Processing Sheet Thickness |

mm |

≤4 |

|

Max Punch Diameter |

mm |

Ø88.9 |

|

Sheet Moving Speed |

m/min |

40 |

|

Punching Frequency |

hpm |

300 |

|

Hole Accuracy |

mm |

±0.1 |

|

Number of Stations in Turret Disc |

No. |

16/24/32 |

|

Turret Rotational Speed |

rpm |

30 |

|

Controlled Axis |

No. |

3/4 |

|

Rotating Location |

No. |

0/2 |

|

Air Pressure |

MPa |

≥0.8 |

|

Outline Dimension |

mm |

4490 x 5300 x 2110 |

|

Machine Weight |

T |

10 |

Features:

1. Equipped with Siemens 3/4 axis CNC system and high-performance AC servo motors for fast and reliable operation;

2. Frame is open-type steel welded structure, tempered for excellent rigidity and minimal deformation;

3. Features secondary positioning function for precise hole punching without dead zones;

4. High-precision international brand transmission system, including large ball screws and linear guides for smooth performance;

5. All pneumatic, electrical, hydraulic components and transmission are perfectly integrated;

6. Uses AMADA standard thick turret disc with international standard molds for versatility.

Notice:

Based on your requirements, we will design the most suitable machine for your workpieces. Please provide the following details:

1. Please inform us about the material of your metal sheets.

2. Provide the dimensions of your workpiece, including length, width, and thickness.

3. Share information about the shapes and diameters of the holes in your workpiece.

4. It would be great if you could send photos or drawings of your products for reference.

We will then provide detailed technical proposals based on this information.

Main Machine Details:

Germany Siemens 808D System;

AMADA Standard 80mm Ductile Iron Thick Turret Disc;

Taiwan Ball Screw & Linear Guide;

International Electrical Components;

Secondary Positioning System.

Feel free to contact us anytime if you have any questions. We welcome you to visit our factory in Qingdao, China.

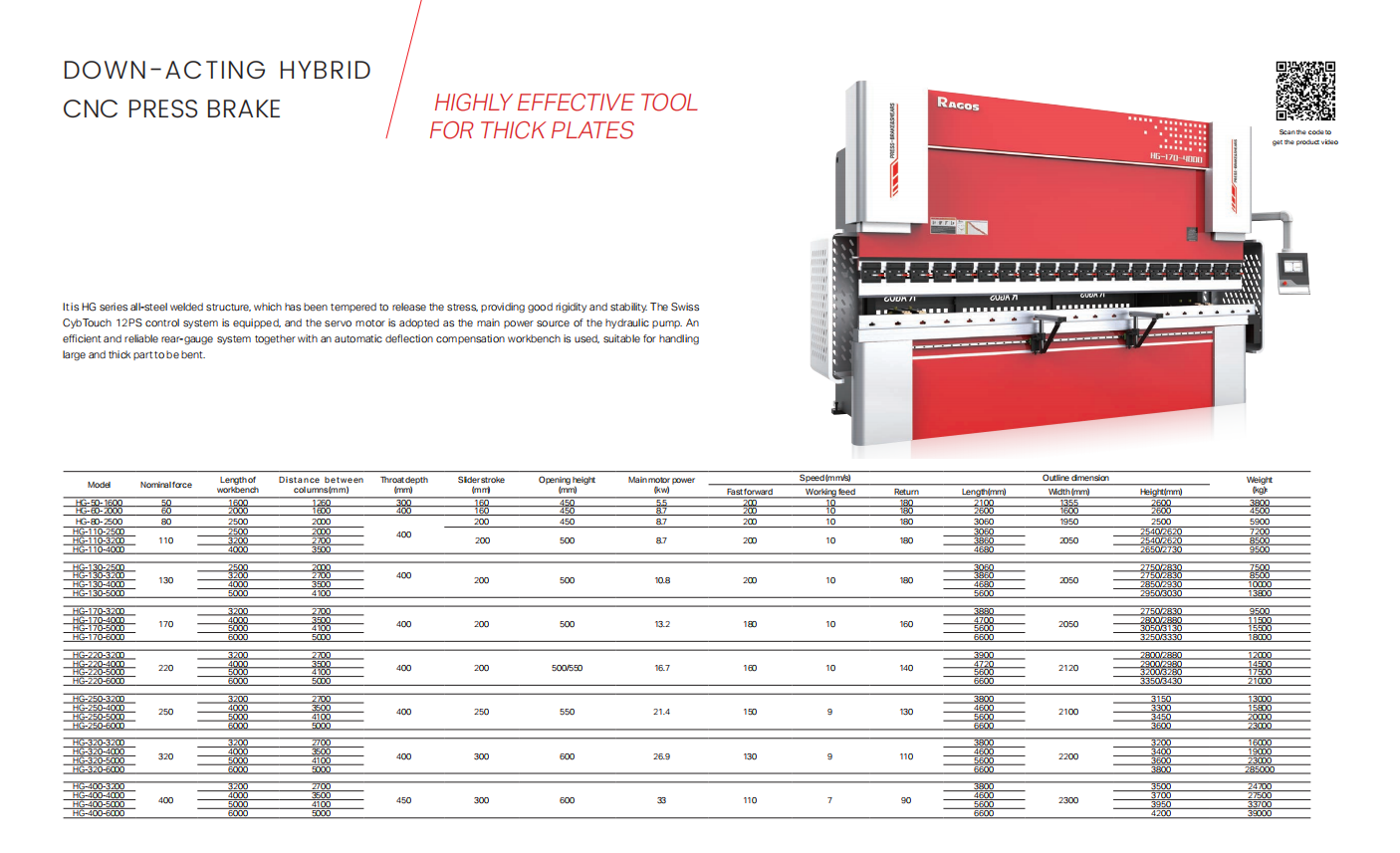

Dual servo hybrid CNC Press Brake

Features:

Introduction:

Features And Function

Fast - 10% performance increase by reducing cycle time

High efficiency - 50% increase in energy efficiency (compared to traditional systems)

Precise - positioning accuracy reaches 0.005mm

Features And Function

Fast - 10% performance increase by reducing cycle time

High efficiency - 50% increase in energy efficiency (compared to traditional systems)

Precise - positioning accuracy reaches 0.005mm

Reliable - minimal risk of leakage

Low Noise - Noise reduction in all operating modes

compact - creating new spaces on the midplane

Compatible - easy integration into CNC

Optimization - less installation and service fees

Environmental protection - the amount of hydraulic oil is greatly reduced

Down-acting press brake,sheet metal panel benders,cnc panel bender,Automatic Panel Bender,Sheet Metal Bending Center,ragos

FOSHAN RAGOS NC EQUIPMENT CO.,LTD. , https://www.ragosnc.com

![<?echo $_SERVER['SERVER_NAME'];?>](/template/twentyseventeen/skin/images/header.jpg)